Why mass flow controller is widely used in various industries?

Abstract

Mass Flow Controller Overview

Are you looking to supply gas, vapor, or liquid to a chemical process with precision and control? Mass flow controllers are the ideal devices for such applications. They find utility in various processes, including:

- Gas dosing into bioreactors for bacterial growth

- Aeration of industrial ice cream or whipped cream

- Supplying odorant to natural gas

In each scenario, achieving a reproducible and accurate supply of chemical compounds is crucial. This ensures controlled processes, optimal product yield, and minimizes the risk of under- or overperformance, such as waste or process run-away.

Learn more about Mass Flow Controllers in 3 Steps

1. How Does a Mass Flow Controller Work?

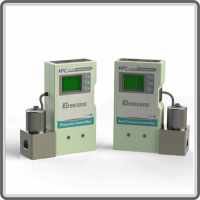

A mass flow controller precisely regulates the flow rate of one or more chemical compounds, whether gas or liquid, into a process. It is a compact device designed for this purpose. The mechanism involves electronic control of the flow rate by setting parameters through voltage, current, or digital sources. An internal sensor measures the flow rate, comparing it with the setpoint value. A control valve is utilized to make adjustments, ensuring alignment between the measured and desired flow rates.

2. Why Control Mass Flow Instead of Volume Flow?

3. Types of Mass Flow Controllers

3A) Thermal Mass Flow Controllers

Thermal mass flow controllers utilize the heat capacity of liquids or gases to regulate their mass flow rates. Within this category, different sensor techniques offer specific advantages:

- Bypass Sensor: Suitable for clean & dry gas applications, ensuring high accuracy and repeatability.

- Inline (CTA) Principle: Ideal for slightly moist gas applications or when robustness is prioritized over accuracy.

- TCS (Trough Chip Sensor) Technology: Combines gas flow and temperature measurement capabilities, making it versatile.

- MEMS Chip Sensor Technology: Perfect for applications with limited space.

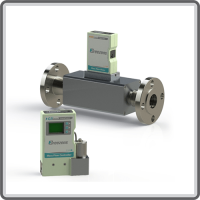

3B) Coriolis Mass Flow Controllers