Understanding Thermal Mass Flowmeters and Their Crucial Role in Oxygen Flow Measurement

Abstract

In various industrial processes, accurate measurement of gas flow is paramount. Particularly, when dealing with critical gases such as oxygen. The efficiency and safety of operations often hinge on precise measurements, making advanced instruments like thermal mass flowmeters indispensable. In this article, we delve into the principles behind thermal mass flow meters and explore their specific applications in oxygen flow measurement.

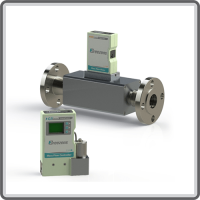

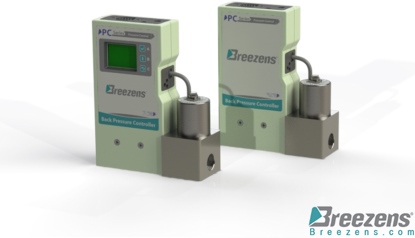

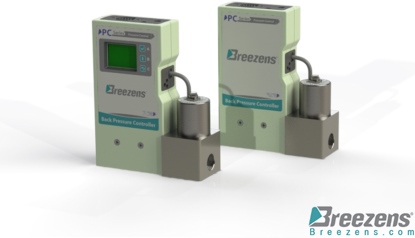

Overview of Thermal Mass Flow Meters

How They Work

Thermal mass flow meters operate on the principle of convective heat transfer. These devices contain a heated sensor and a temperature sensor. The gas, flowing through the meter, takes away heat from the heated sensor. The temperature sensor gauges the cooling effect, and the dissipation rate of heat is directly proportional to the gas’s mass flow rate. This correlation ensures precise measurement without requiring extra pressure or temperature compensation.

Advantages

- Wide Range of Applications: Thermal mass flowmeters are versatile and find applications in various industries, including pharmaceuticals, petrochemicals, and semiconductor manufacturing.

- Low Pressure Drop: These flowmeters typically have a low-pressure drop, minimizing the impact on the system in which they are installed.

- Low Maintenance: With no moving parts, thermal mass flowmeters require minimal maintenance, contributing to their reliability in long-term use.

Applications in Oxygen Flow Measurement

Precision in Medical Applications

Industrial Processes

Environmental Monitoring

In environmental monitoring, the measurement of oxygen flow is integral to understanding and managing air quality. Thermal mass flowmeters assist in gathering accurate data for regulatory compliance and environmental conservation efforts.