Technological advances in the Haber process (catalyst)

Abstract

Catalytic research on the Huber process, discussed here, shows that the use of thermal flow controllers and flow meters from Breezens can improve the performance of gaseous chemical reactions. They will also provide more precise control over the process.

Introduction

An example of catalytic research discussed here is the “Haber process.” In this process, ammonia is produced on an industrial scale for use in fertilizers. The “Haber process” converts nitrogen and hydrogen into ammonia using a metallic catalyst at high temperatures and pressures. Catalytic research is continually evolving as better catalysts are constantly being discovered. Initially, the “Haber process” used osmium as a catalyst. Currently, the catalyst type is iron-based.

Research on catalysts takes place in a pilot plant. A pilot plant, by providing valuable initial scientific data about reactions, material properties, process yields, and other factors, reduces the technical and commercial risks associated with large-scale process plants. It also enables monitoring of tests encompassing all parameters, including pressure, temperature, flow rate, and reaction time. The goal is to improve process yields or develop new processes with higher efficiencies.

Process Requirements

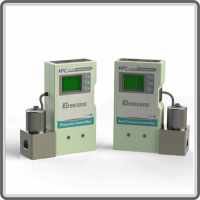

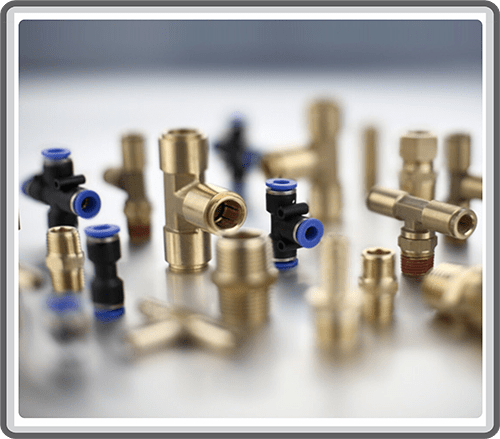

The “Haber process” typically begins with two thermal mass flow controllers (MFCs) from Bronkhorst. One MFC injects nitrogen, and the other injects hydrogen into the stream. In this process, the N2 to H2 ratio is 3 to 1. The common pressure and temperature for this reaction are 1450 PSI and 750 to 930 degrees Fahrenheit.

Features of the Mass Flow Controller Device

- Accurate and repeatable gas flow using mass flow controllers to ensure precise gas ratios

- Long-term sensor stability or continuous accuracy over time through digital communication protocols such as EtherNet/IP or PROFINET

- Available certifications including ATEX, ISO, and EMC

Process Solution

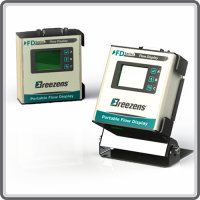

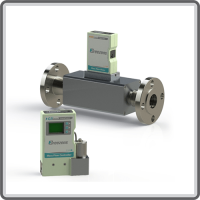

Two mass flow controllers precisely measure vital gas flow to activate the reaction. After the process occurs in the catalyst beds, the gas exits the reactor. Then, this gas passes through a series of heat exchangers and condensers. Upon entering the cooling unit, ammonia becomes a liquid. As it exits the cooling unit, ammonia can be measured and controlled by Breezens thermal mass flow meters.