Increasing the quality of vacuum cleaner by using Mass Flow Meter (MFM) and Mass Flow Controller (MFC)

Today’s vacuum cleaners have different categories in terms of suction power, pollution removal, easy operation, lifespan, motor sound, efficiency, power consumption, and design. Although the job of all vacuum cleaners is to suck garbage into itself, the improvement of these items will increase the quality and as a result, encourage more and more buyers.

In all the standards, the ideal conditions for a vacuum cleaner have been completely described, and their realization as best as possible helps in achieving higher quality.

Some examples of the most important ones are as follows:

-

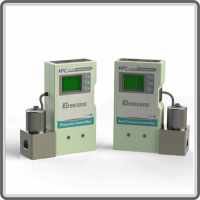

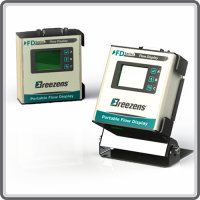

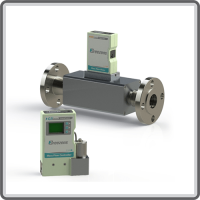

To calculate and measure a vacuum cleaner’s output power (suction power) using Mass Flow Meter (MFM) and Mass Flow Controller (MFC), the airflow and relative vacuum pressure must be adjusted to achieve the best suction power.

-

During making a vacuum cleaner, it is necessary to test the output power of the vacuum cleaner several times, which is done by correcting the air density according to the environmental conditions. Mass Flow Meter (MFM) and Mass Flow Controller (MFC) play a very influential role in advancing these tests.

-

Most comparisons in vacuum cleaners are made using efficiency. Vacuum cleaner efficiency is defined by dividing the output power (suction power) by the corrected input power. Product efficiency is considered an energy efficiency index. The energy category of the product is classified exactly on this basis. Therefore, the most important goal of producers is to somehow increase efficiency, which can be achieved by using functional equipment such as Mass Flow Meter (MFM) and Mass Flow Controller (MFC).

-

Another important factor in promoting a product like a vacuum cleaner is its cleaning power. The effect of proper Mass Flow Meter (MFM) and Mass Flow Controller (MFC) performance is very important in terms of accuracy and error reduction in measuring the cleaning power and testing the cleaning power of a vacuum cleaner.

-

Increasing competition

-

Accurate comparison of products by buyers,

-

Reducing the accuracy and quality of manufactured products due to non-observance of defined standards and use of appropriate measuring equipment

-

Cost increase, such as the cost of troubleshooting the production line if there is an error resulting from the measurements

-

The adverse effect of errors on other production lines and damaging them