Increasing the quality of gas stoves and ovens using Mass Flow Meter (MFM) and Mass Flow Controller (MFC)

Many people consider the kitchen to be the heart of the home. This heart will not beat unless there is a gas stove in it to spread the delicious smell of food. The safety of gas stoves is very important because they are used several times a day, and the slightest indifference to the safety of gas stoves can cause gas leakage, ignition or explosion, and even death.

In the following, some simple points are stated in the standards, which compliance helps a lot in the production of quality and safe products.

-

Pressure regulator as a controller that maintains pressure at a specified value during normal use and should not change spontaneously without readjustment.

-

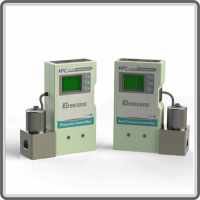

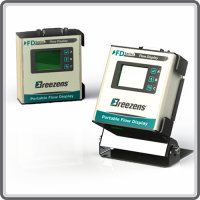

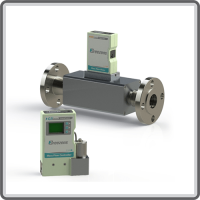

The pressure release device is a controller that controls the gas pressure under abnormal working conditions. It is quite clear that for safety as much as possible, it is necessary to monitor and control the conditions of gas emission in all conditions (normal and abnormal) so that maximum reliability can be obtained. The use of Mass Flow Meter (MFM) and Mass Flow Controller (MFC) is very practical and reliable for measuring and controlling gas.

-

Nominal cooking pressure, the maximum working pressure of pressurized steam ovens marked by the manufacturer on the primary pressurized parts. To measure as accurately as possible, it is necessary to provide the initial pressure conditions using Mass Flow Meter (MFM) and Mass Flow Controller (MFC).

-

In one of the tests that take place after production, a specific amount of CO and CO2 gases are injected, and according to the concentration and volume of these two gases, they must release a specific heat, which can be achieved by accurately measuring these gases.

-

Automatic gas cut-off when there is no flame and proper adjustment and distribution of gas when more than one flame is on are two important things that significantly increase safety in gas stoves and ovens. Continuous control and measurement of the gas path can be entrusted to Mass Flow Meter (MFM) and Mass Flow Controller (MFC)

-

Increasing competition

-

Accurate comparison of products by buyers,

-

Reducing the accuracy and quality of manufactured products due to non-compliance with defined standards and the use of appropriate measuring equipment, which greatly increases the possibility of gas leakage, gassing, suffocation, and even death.

-

Cost increase, such as the cost of troubleshooting the production line if there is an error resulting from the measurements

-

The adverse effect of errors on other production lines and damaging them

These are only part of the concern of the producers, which if not followed, will increase the failure in production day by day. By using the right equipment, this concern can be turned into a strong point of production and it can be easily surpassed in the competition with other manufacturers and play an important role in saving people’s lives.