Abstract

Flow controllers play a crucial role in various industrial processes, including biological, chemical, food, and manufacturing applications. This blog introduces the concept of flow controllers, their functionality, and the diverse types available. The controlled supply of fluids, whether gases, liquids, or vapors, is essential for achieving precise and efficient processes. Accurate flow control not only enhances final product quality but also contributes to improved process understanding, potentially expediting process steps and boosting overall process economics.

Flow Controllers: An Introduction

In the realm of biological, chemical, and manufacturing processes, as well as analytical pursuits, the need for controlled fluid supply is evident. Flow control, defined as the regulated delivery of fluids (gases, liquids, or vapors), is paramount in these applications. The utilization of flow controllers, specialized devices designed for flow control, becomes essential to achieve accurate and efficient processes.

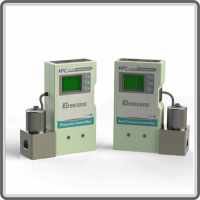

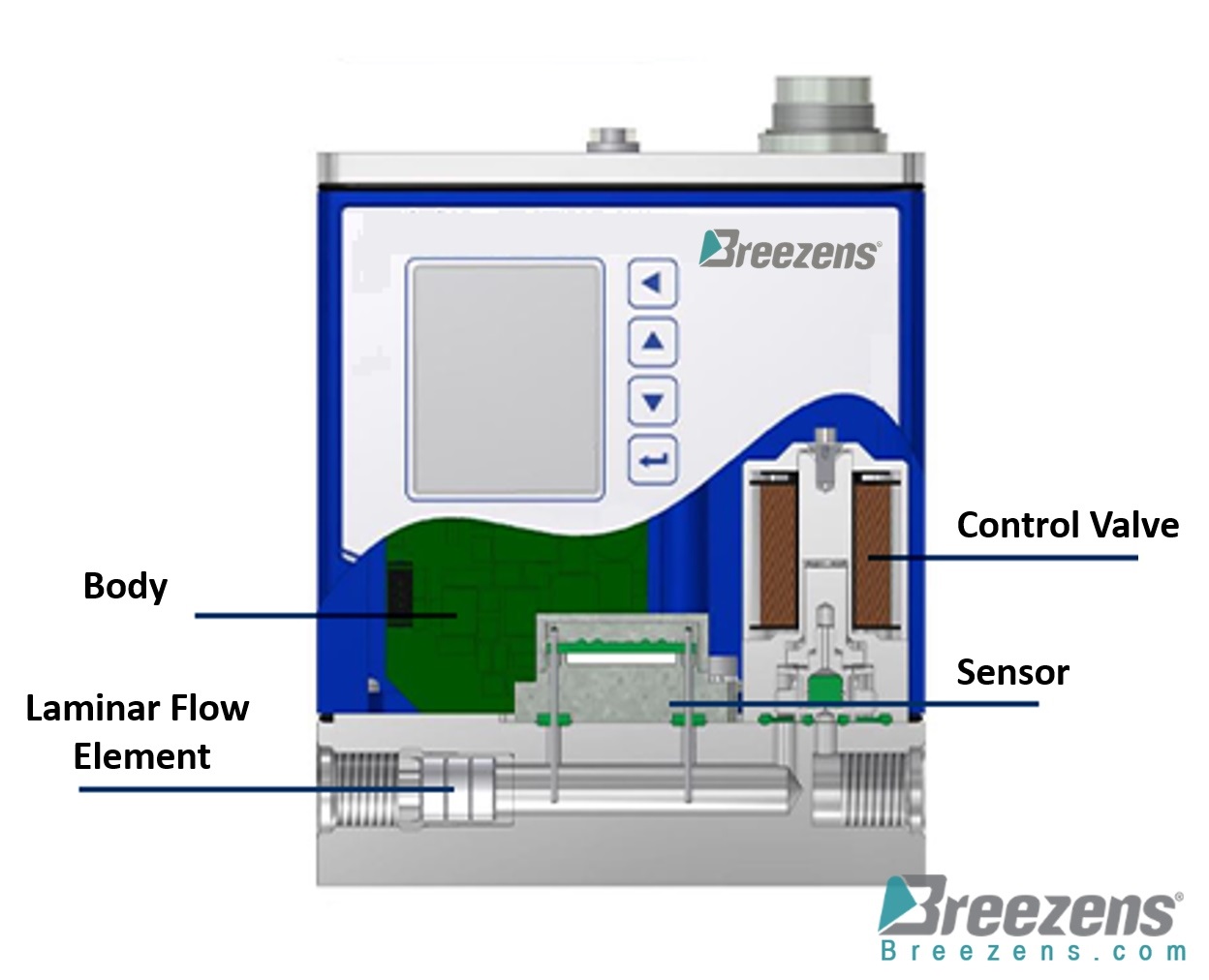

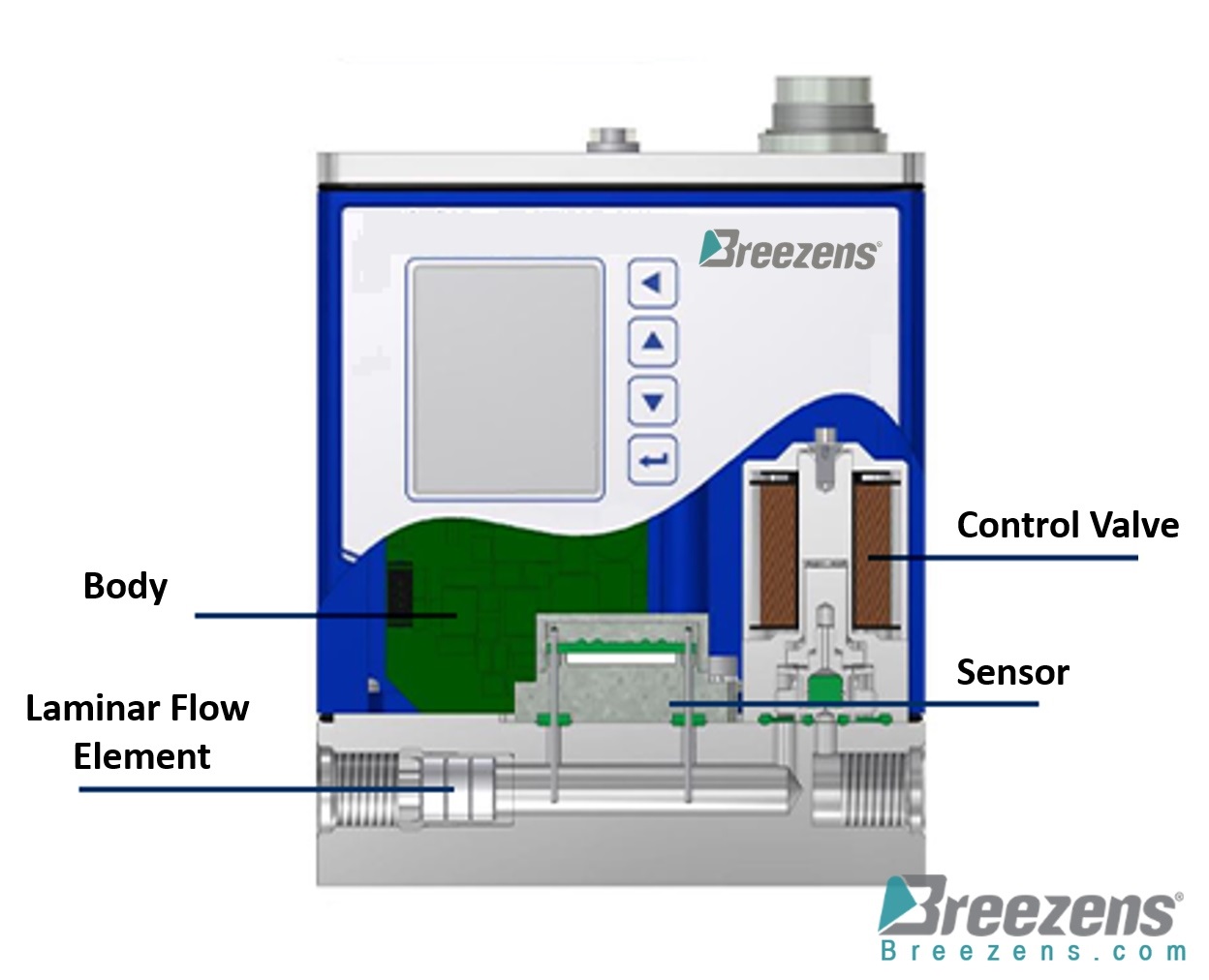

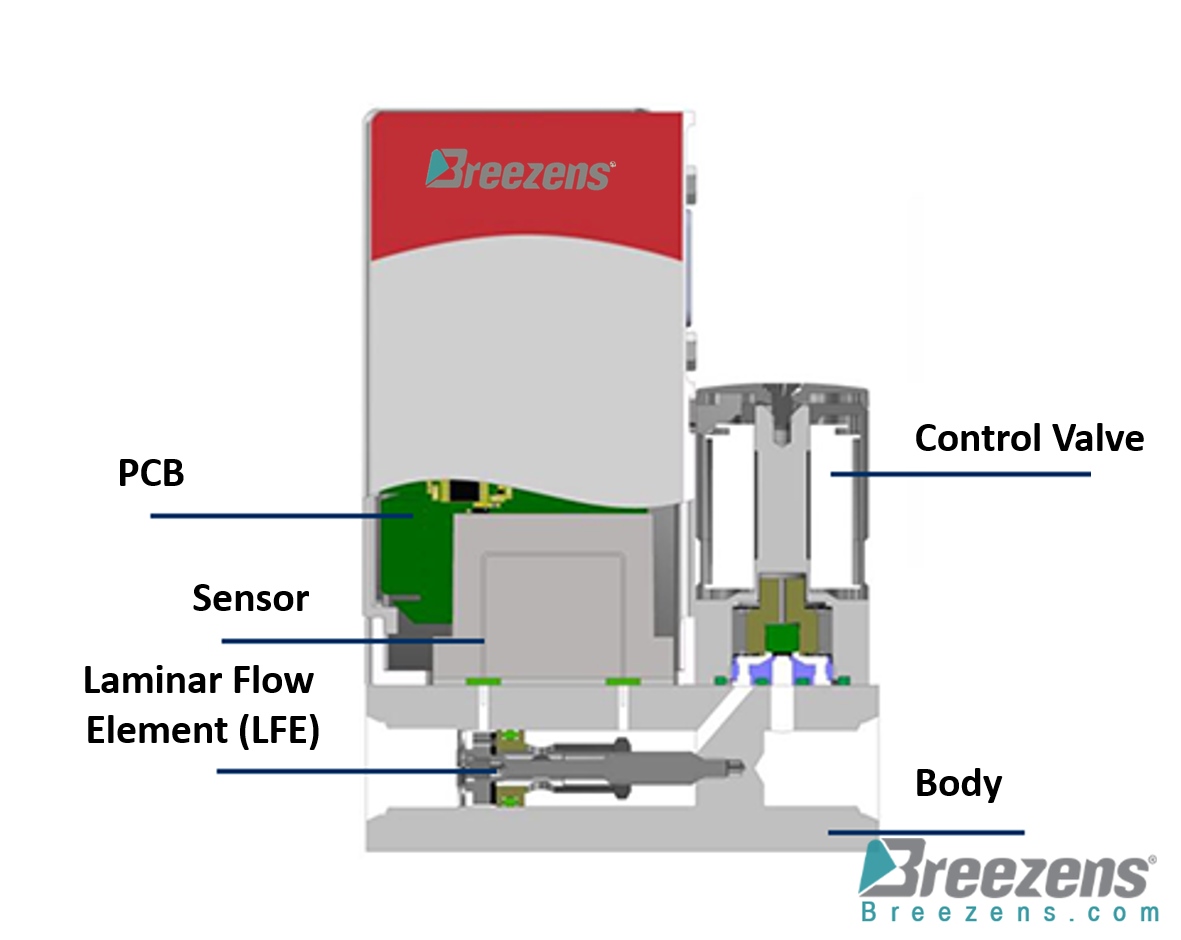

What is a Flow Controller?

A flow controller serves the purpose of introducing one or more chemical compounds in gaseous, vapor, or liquid form into a process by regulating the compound’s flow rate. This can be expressed either as a mass flow rate (in grams per minute) or a volumetric flow rate (in liters per hour). Mass and volumetric flow rates are interrelated through the density of the compound, making them convertible. In practical applications, mass flow is often preferred, but volumetric flow controllers cater to users accustomed to working with volume units.

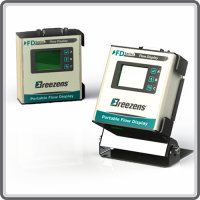

Types of Flow Controllers

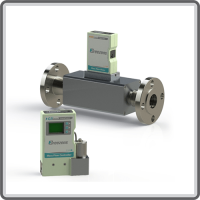

Flow controllers vary based on sensor types, with thermal, Coriolis, ultrasonic, and positive displacement principles being prominent.

-

Thermal Principle:

- Bypass sensor

- Constant Temperature Anemometry (CTA) principle

-

Coriolis Principle:

- Directly related to fluid mass flow rate and mass inertia

-

Ultrasound Technique:

- Measurement of volumetric liquid flow rates through ultrasound.

-

Positive Displacement Principle:

- Utilizing a gear pump for volumetric flow control.

These controllers cater to diverse applications, with some designed for gases, others for liquids, and some versatile enough to handle both fluid types. The selection depends on the specific requirements of the process.