Summary

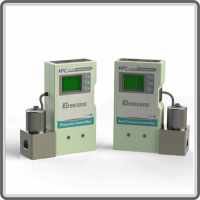

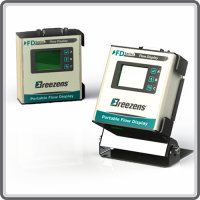

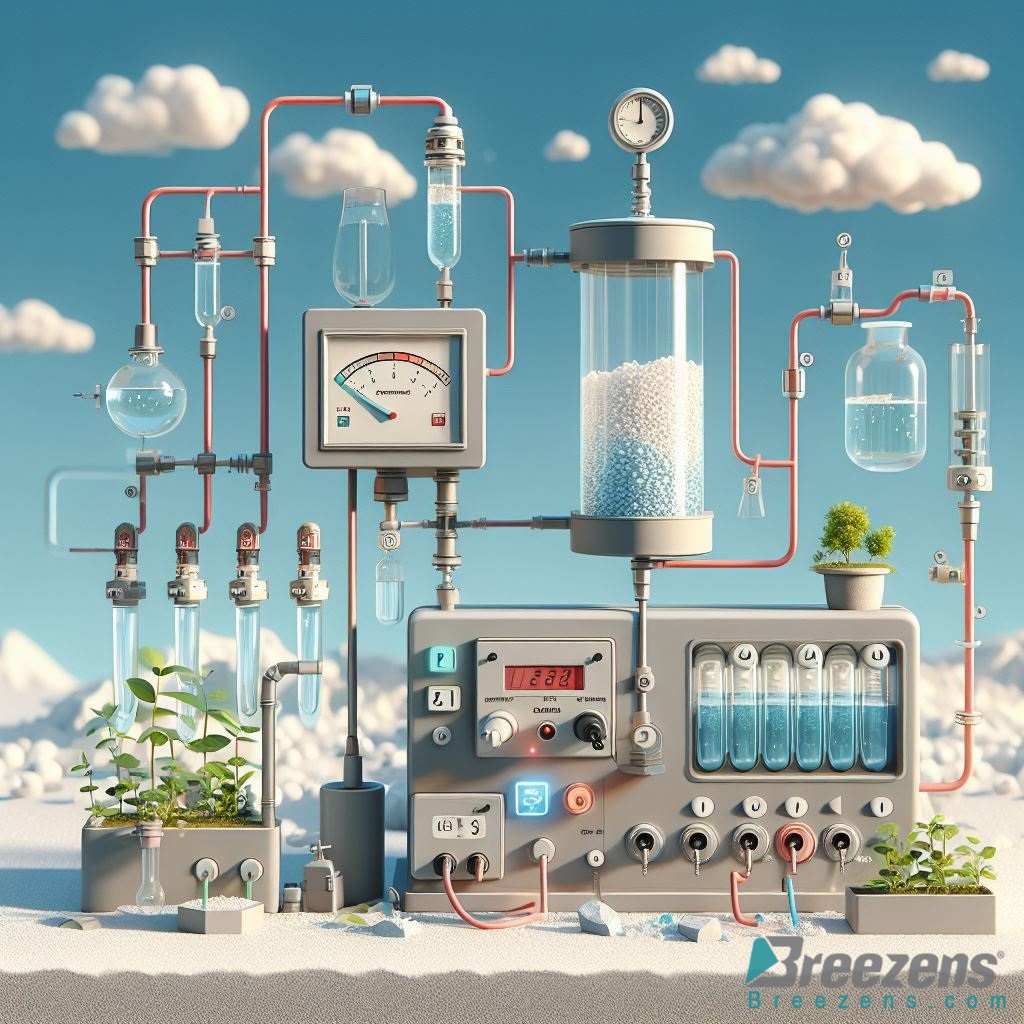

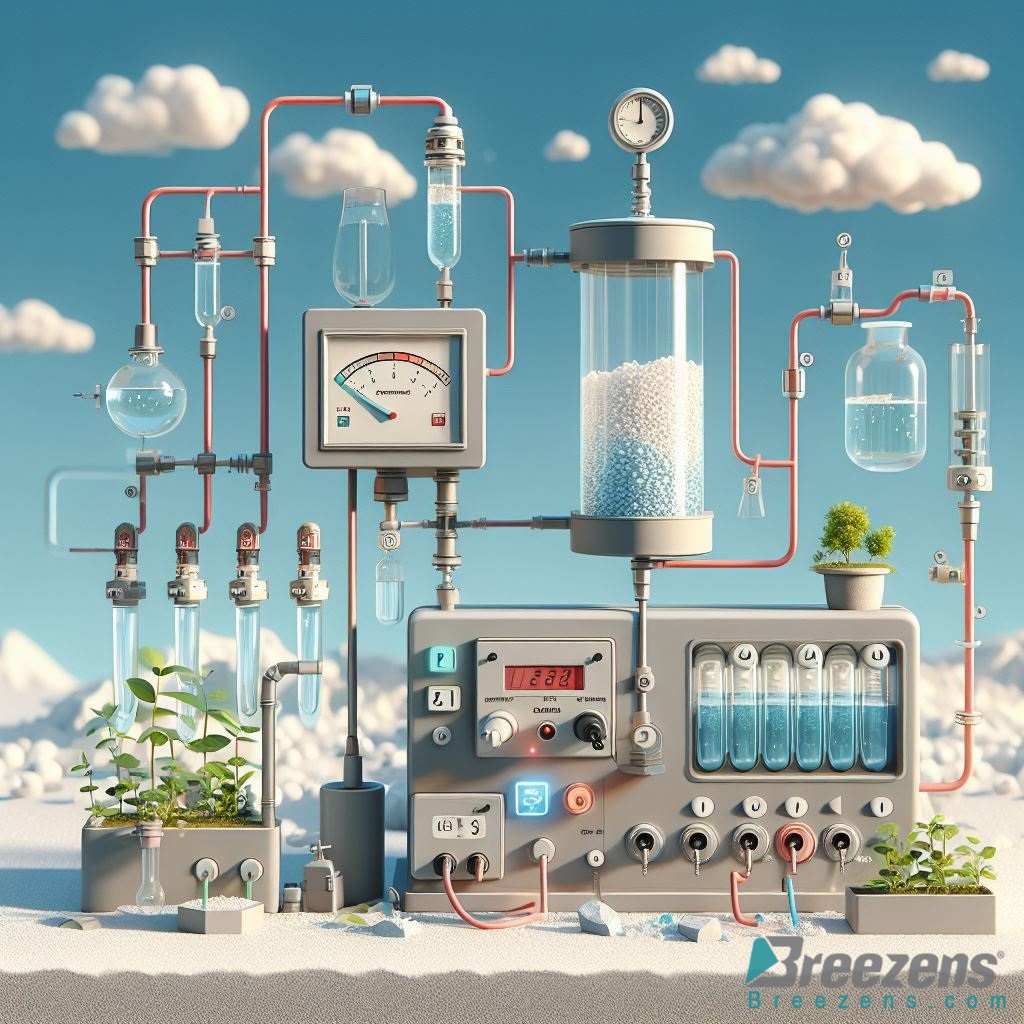

Flow controllers are used in the catalysts industry to control and regulate the flow of gases in chemical processes. Flow controllers are used to maintain optimal conditions in order to maintain stability and improve product quality. For example, these devices are used to control the flow of air, water, gas and chemicals in catalyst production processes.

Catalyst

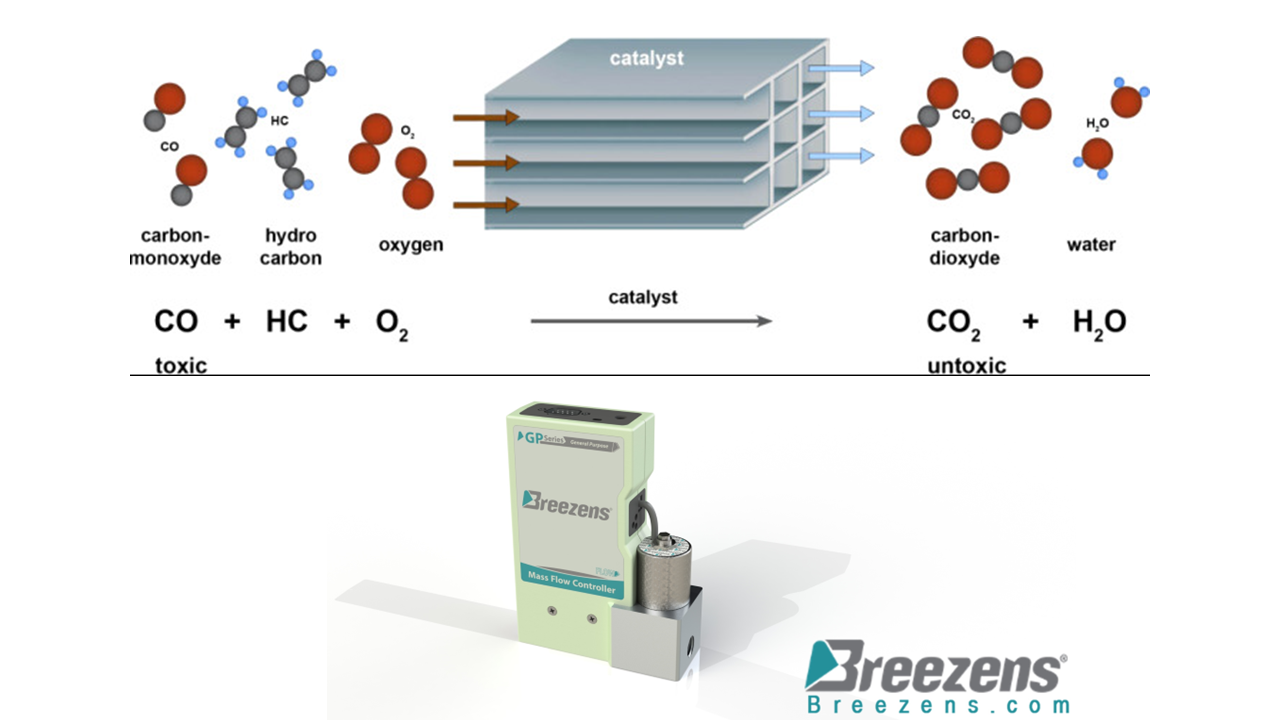

Catalysts are used to accelerate and improve chemical processes in the chemical industry. These materials are used in industries such as the production of polymers, the synthesis of electronic components, the production of fertilizers and floor coverings, the production of basic chemicals and the production of basic chemical materials. In catalyst production processes, precise controls are required to maintain optimal conditions for catalyst activity; For this, flow controllers are used to control the flow of gases in catalyst production processes.

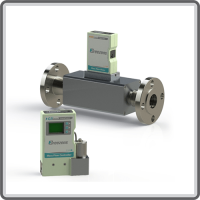

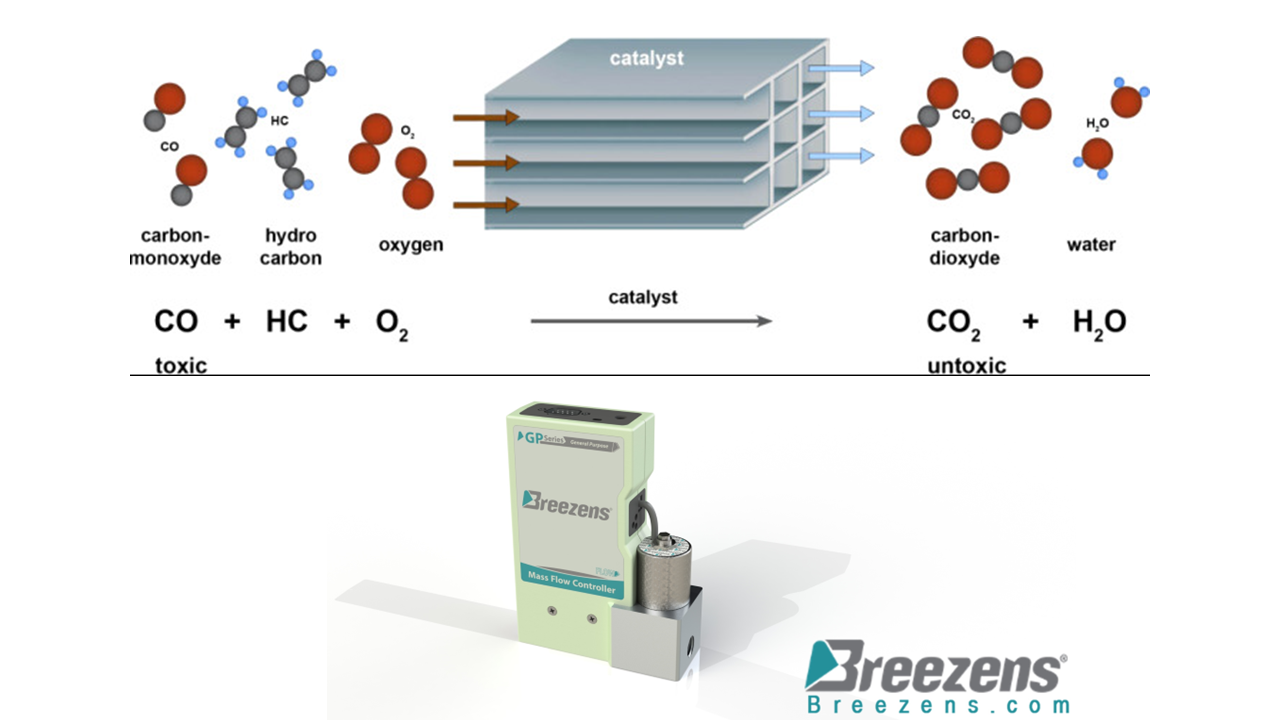

In checking the performance efficiency of the automobile catalyst, a test is performed with the presence of the flow controller. The validation process is such that the composition of the gases entering the catalyst and the percentage of its components are measured and controlled by flow control, on the other hand, the gases exiting the catalyst are analyzed; Therefore, by determining the composition of the exhaust gases and its performance in converting harmful gases into greenhouse gases, the correctness of the catalyst performance is evaluated.