Abstract

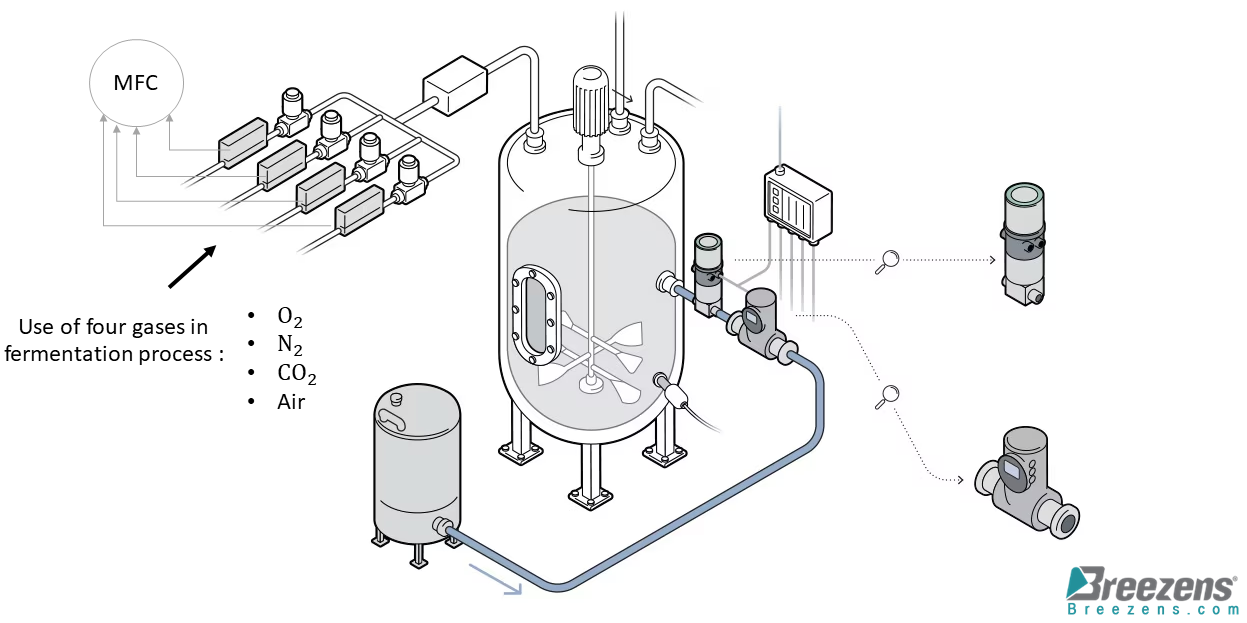

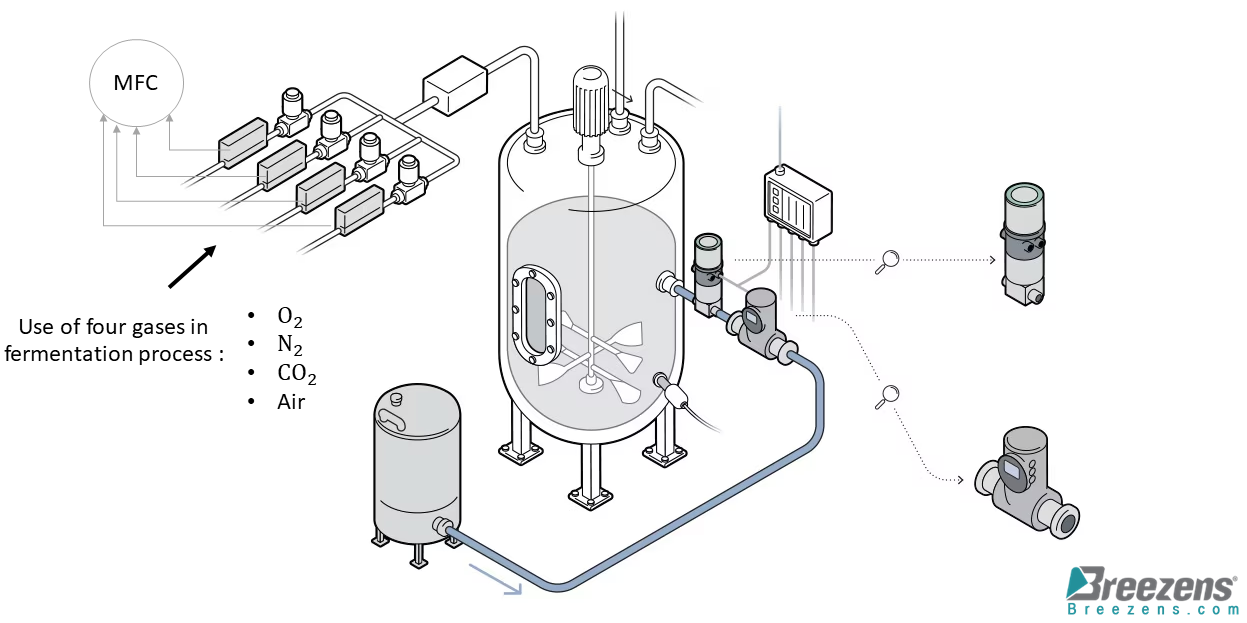

A fermentor is a device that needs to measure and control the gas flow in the pharmaceutical industry to carry out the fermentation process. Thermal mass flow controller and thermal mass flowmeter are equipment used to control and measure gas flow. These devices can be used in laboratory and industrial environments. In this blog, we will explain more about the relationship between the fermentor and the thermal mass flow controller.