Introduction Of Leak Test Technologies

Many technologies are used in the field of leak measurement and testing in the industry, including Immersion in Water technology, Helium Leak Spectrum detection, Gas Tracing, Absolute Pressure, measuring the difference in pressure “Differential Pressure” and “Mass Flow Measurement” pointed out that each of the above methods has advantages and disadvantages. In the table below, the advantages and disadvantages of each method can be seen at once.

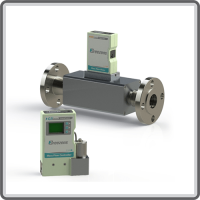

Thermal mass flow measurement technology is based on the amount of heat transfer of particles in contact with a hot element and with the help of flow separation technology, it has the ability to measure any movement of particles in a closed environment. This capability is very valuable in leak test systems because the presence of gas fluid leakage in any chamber with any structure shows itself in the form of directional movement of the fluid inside the chamber and can be measured based on the thermal mass method.

Advantages and disadvantages of

Thermal Mass Technology In Leakage Testing

> The ability to measure the amount of

leakage

> High measurement accuracy

> Ability to measure leakage both in parts

under pressure and in parts under vacuum

> Measuring the amount of leakage

independent of the location of the leak in the

part

> Measurement of the total leakage of the

part

> Performance independent of operator

performance accuracy

> Ability to use all gases as test fluid

> No dependence of measurement accuracy

on pressure changes

> High repeatability

> Wide leakage measurement range

> Carrying out the measurement process

completely dry and without moisture

>Reasonable supply price

>Small dimensions

> Portability

> Easy calibration capability

> Ease and cost-free maintenance

> Ability to fully automate the leak detection

process

× Failure to identify the location of the leak

× Dependence of the leakage measurement

time on the volume of the part under test

! It should be noted that the location of the leak can only be accurately identified with the helium tracking method, and by modifying the route of gas injection to the part under test, the dependence of the time of the leak test process on the dimensions of the part can be reduced

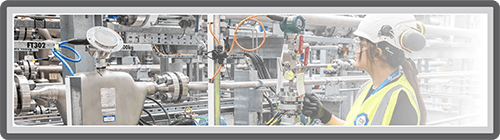

Leakage testing in the automotive industry

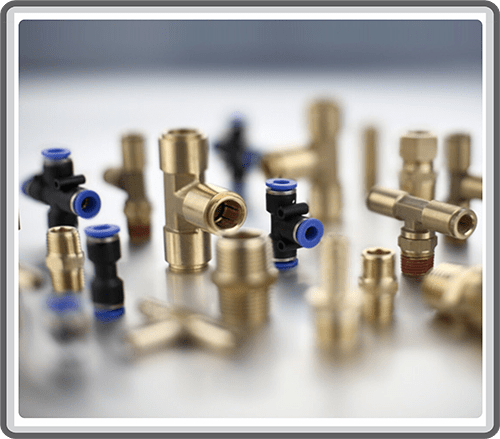

Four very large industries are the main consumers of leak testing devices. Automotive industry, hospital equipment and facilities, production of industrial parts and packaging industry in the automotive industry, the use of the leakage test process is very extensive, from injection plastic parts to parts made by welding, casting, diecast forming, etc., which include The following can be mentioned:

> Engine parts such as cylinders, pistons and

>Suspension system such as shock absorbers

>Engine and room ventilation system such as

cooler gas tank, water pump

>Exhaust and discharge system such as tanks

and catalyst holder

>Main lights

>Fuel tank and system such as gas station

>Safety system such as airbags

Technical specifications

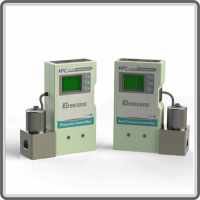

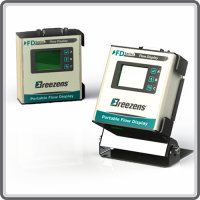

Technical facilities and capabilities

Other advantages of Breezens leak test device

One-year warranty and ten-year after-sales service

According to the existing restrictions in commercial interactions with other countries, benefiting from guarantees such as warranty for the buyer Iran is limited and many foreign manufacturers shy away from accepting this responsibility, providing products and services By the Iranian manufacturer, it resolves the conflict with such issues.

Support and after-sales service available

Due to the production of the heart of the leakage test device, the mass flow measurement sensor, the possibility of providing support services is available in the Breezens collection And the service and calibration are available and fast for the customer. This is while benefiting from the services Selling for foreign devices takes a lot of time and is subject to heavy costs.

Portableness of the Breezens leak test device

The portability of the leak test device produced in Breezens collection provides the customer with the possibility that without the need To stop the line by having a replacement device, send the device that needs service, and in this way, instead of waiting for dispatch An expert and visiting the device at your place will be unnecessary.

Ability to customize

Due to the wide variety of parts that need to be tested for leakage, including large and small parts, parts with elastic properties Sunny and elastic or rigid, parts of different materials, as well as different testing processes, need to be customized Construction is very important in the manufacture of leak testing devices. This possibility is very limited in foreign purchases And the conditions for holding technical meetings between the manufacturer and the employer are provided with difficulty and at a high cost, while the knowledge and The manufacturing experience available in Breezens collection provides the possibility of any customization for all kinds of parts.

Competitive price and riyals

Despite the facilities provided, it is completely competitive with foreign products, the supply price of Breezens products is about 30% of foreign devices, and the financial interaction of Rial brings the comfort of the imagination of the price of currency to the Iranian buyer.

Some of Breezens’s customers

Breezens leak testing and measuring device, along with brands such as FORTEST and ATEQ, which are reliable and well-known brands in the field of manufacturing leak testing equipment and have had the major market share in Iran for many years, has been able to achieve a price of about 30%. The price of the mentioned brands and with competitive quality should be entered into this arena. ![]()

![]()